A Brief Overview of the Various Types of Extruders Used Prior to the Spheronization

Extruders are described below …

In the pharmaceutical industry, extrusion is the necessary first step in the extrusion-spheronization process. However, extrusion is often used to eliminate dust in formulations even when spheronization is not the final objective. The choice between gear and screen extruders depends on the formulation characteristics and the required density of the extrudate. Therefore, the right equipment for you would depend on the specific needs of your application.

There are Three Main Types of Extruders (Although There are Other Variations on These Basic Types)

- Screw Extruders

- Screen (or Basket) Extruders

- Gear Extruders

Types of Extruders:

Screw Extruders

- Commonly used in industrial applications

- Higher pressure and heat can degrade pharmaceutical products

Screen, or Basket, Extruders

- Commonly used in pharmaceutical industry

- Lower density extrudate

- Relatively high throughput

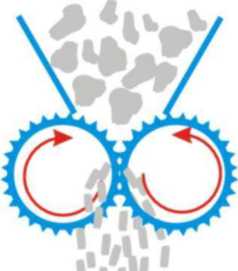

Gear Extruders

- Commonly used in pharmaceutical industry

- Produces a relatively higher density extrudate

- Gentler on product

- Gears are robust and and last longer

4. Optimum Shape for Coating and for Controlled Release:

Coating can provide controlled, targeted release at different locations within the body. Important for effective release of some drugs.

Other Types of Extruders

Cylinder Extruders

The cylinder type consists of two contra-rotating cylinders, one of which is solid. The second cylinder is hollow and has a series of holes drilled through it. The material to be extruded is fed into the area above the two cylinders and is extruded into the bore of the larger perforated cylinder where it is cut into lengths by an adjustable cutter blade.

Radial Extruders

The radial and axial type of extruders consist of one or two feed screws that force the material either through a circumferential screen in the radial type, or through a die head in the case of the axial type.

Table Summarizing the Different Types of Caleva Extruders For Pharmaceutical Production and Development

Types of Caleva Extruders |

||

|

Equipment

|

Description

|

Main Uses

|

| Caleva Multi-Lab With Screw Extruder Attachment | Mixer-Granulator, Extruder and Spheronizer in one small, bench top unit. | Laboratory: small quantity (10g) development use |

| Caleva Variable Density Extruder | A bench top extruder capable of using both radial and axial extrusion methods. | Laboratory: Smallest batch is about 15 grams. |

| Extruder 20 | Bench top screen extruder | Laboratory

experimental / small scale production (30 g 25 kg /hr) |

| Extruder 35 | Production screen extruder | Lab/Production

Low cost-high output (2kg /min) of less dense extrudate |

| Extruder 40 | Production gear extruder | Quality Extrudate

Output 40-100 kg/hr |

| Extruder 100 | Production gear extruder | Quality Extrudate

Output 100-500 kg/hr |