A Continious Production Spheronizer for Spheronizing Pharmaceutical Compounds

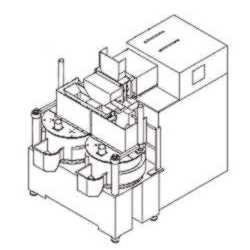

Designed for continuous production applications, the unit provides a dual drum spheronizing facility. Two contra rotating drums are auto sequenced to continuously load, spheronize and discharge the product.

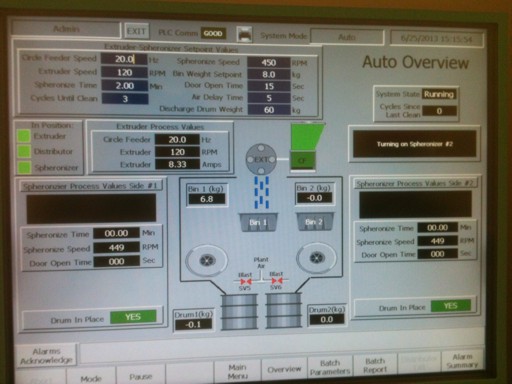

Optional accessories include full PLC control, automated batch weighing/loading, drum heating/cooling, and inverter drive for fully automatic speed control. Specifications allow the Spheronizer 700 and 700T to run continually for 24 hours per day. A pneumatic hoist is built into the units to enable easy lifting of the spheronizing discs for cleaning and maintenance.

Typical batch weight can vary from 5kg to 25kg per spheronizer drum. Productivity per hour will vary depending on the required process time which, in turn, will depend on the characteristics of the material and the required quality of the spheroids that are produced.

The application shown above has full automation capabilities, utilizing 21 CFR Part 11 compliant software and GAMP4 documentation. It integrates a conveyor infeed to a Caleva Extruder 100, calibrated batch collection hoppers and an automated Caleva Spheronizer 700 Twin.

Features

- Designed for the production of smooth, regular spheroids of material.

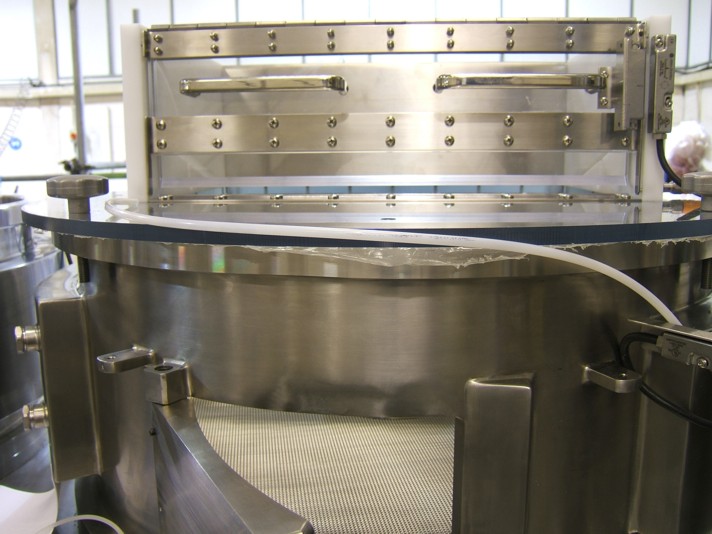

- All contact parts in 316 stainless steel or Perspex

- Cabinet in 304 Stainless Steel.

- Two contra rotating drums are auto sequenced to continuously load, spheronize and discharge the product.

- Special features to meet individual requirements.

- Can be supplied with integrated Caleva extruders or extruders produced by others

- A full automation package is available for bringing the batch process close to a continuous process, integrating extruder infeed and speed, batching of the extrudate, and automation of spheronizer cycles

- It integrates a conveyor infeed to a Caleva Extruder 100, calibrated batch collection hoppers and an automated Caleva Spheronizer 700 Twin

- Production can be greater than 600kg per hour, depending on product

Options

There are a number of options available to suit the requirements of your application. Please discuss your project with us so we can determine which options are suitable for you.

The options available are:

- Heating/Cooling jacket on drum.

- Alternative discs.

- PTFE/FEP anti stick coating (FDA approved materials) for discs, drums.

- Explosion-Proof design.

- Manual loading hoppers and loading hoppers with PLC control.

- Proximity detector to prevent operation if no collection bin in place.

- Full Allen Bradley or Siemens PLC based based control and monitoring system, 21 CFR Part 11 compliant.

- Custom integration with your plant's MES/MRP system.

- Automatic WIP cleaning system.

- SCADA package.

Specs

| Diameter of Spheronizer Disk: | 685 mm x 2 |

| Weight: | Approx. 1400 kg |

| Size: | 304 SSApprox. 180x175x120 cm, or to customer specification |

| Disk Speed | between 200 and 800 RPM |

| Motor: (Power) | 7.5Kw motor per disc, with inverter |

| Controls: | Fully automatic operation is available. Full PLC control is available and is designed to customer specifications. Full specifications can be decided only after discussion with the customer. |

| Minimum Load: | The effective minimum load requirement is about 5g. |

| Utilities: | 3 Phase to customer requirements. Clean, dry compressed air. USP water if WIP feature is purchased. |

| Working Capacity: | Up to 600kg/hour is possible, (depending on product and operational factors) |

| Specifications may be subject to change without notice. | |

Videos

There are no videos for this product.